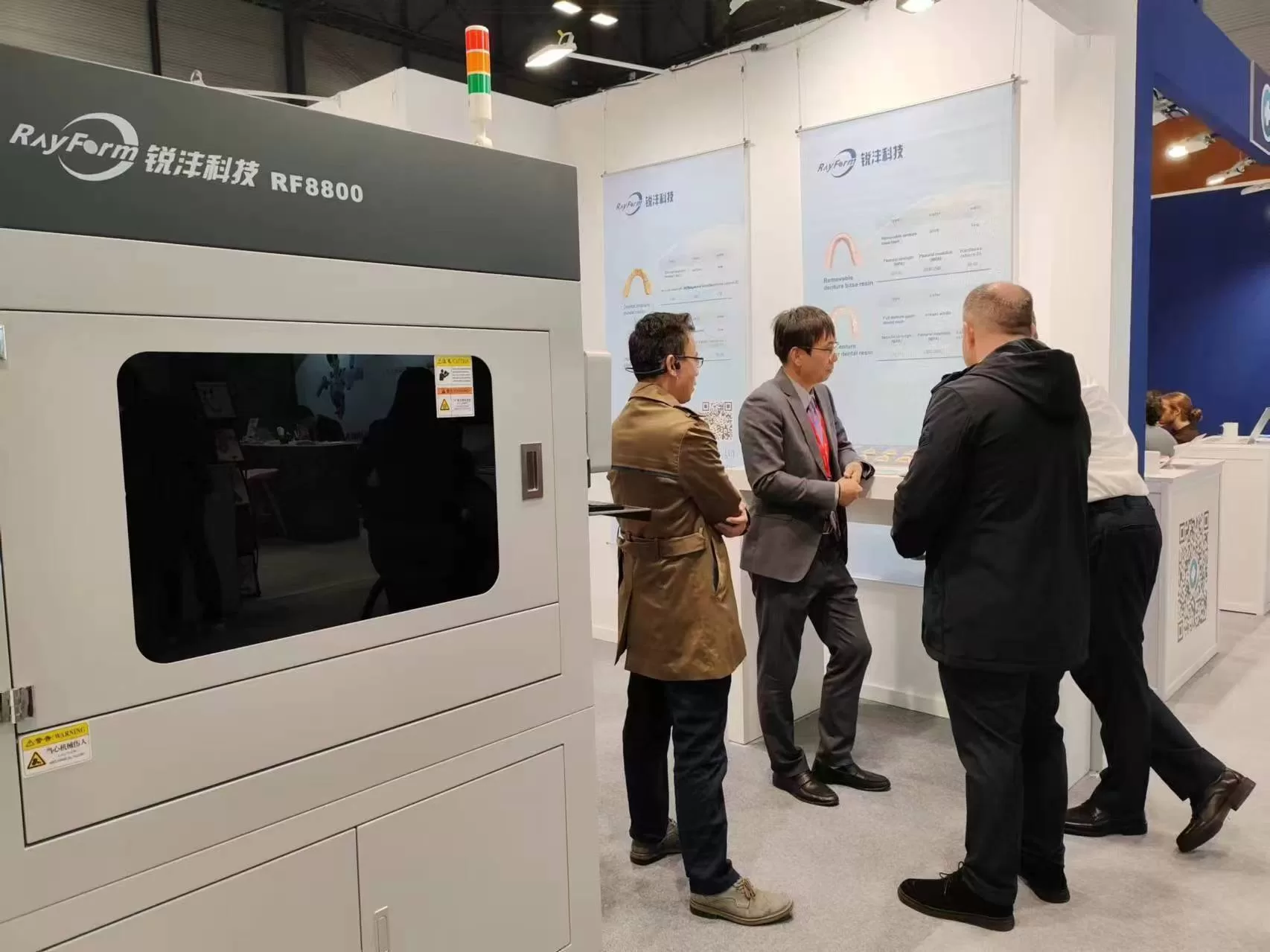

RayForm 3D Printing Dental Resin Showcased at IFEMA Madrid Dental Exhibition 2024

On March 14, 2024, dental professionals, manufacturers, and technology leaders gathered at IFEMA Madrid for one of the most anticipated events in the dental industry — the International Dental Exhibition. RayForm Technology’s water-free dental resin and water-washable 3D printing material are designed with environmental friendliness and greenness as their top priorities. Among the most groundbreaking technologies showcased, 3D printing dental resin took center stage, revolutionizing the way dental model appliances.

Rise of 3D Printing in Dentistry

With increasing demand for precision, speed, and customization in dental solutions, 3D printing technology has become a key driver of innovation. At IFEMA Madrid, RayForm demonstrated how advanced dental 3D printing resin enables the creation of accurate, biocompatible dental models, crowns, bridges, surgical guides, and clear aligners — all within a drastically reduced production time.

RayForm More Dental Resin Model

RayForm unveiled their latest high-performance dental resins, including light-curing materials optimized for ultra-fast printing, high wear resistance, and exceptional accuracy. Visitors had the opportunity to explore the Ultraprint Dental Series, specially formulated for orthodontics, prosthetics, and implantology. These resins support high-throughput, automated production environments — a major theme of this year’s exhibition.

3D printing dental model resin product series

RayForm, as a company that has been dedicated to the analysis and research of 3D printing materials for many years. Now, there have been numerous breakthroughs in material research and development for various applications. Since 2018, when it began to focus on the 3D printing material market, the company has attracted the attention and cooperation of many domestic and foreign brand distributors with materials outstanding functional characteristics.

Automated Production for Clear Aligners

One highlight of the RayForm in exhibition was the fully automated production solution for transparent orthodontic aligners. Combining industrial-grade 3D printers, dental-specific resins, and post-processing systems, manufacturers now achieve seamless production workflows from digital scan to final product. This automation not only reduces labor costs but also enhances quality control and consistency — a game changer for orthodontic labs and dental clinics alike.

RF-8800 3D Printer boast a fully automated system, featuring capabilities forautomatic removal, sorting, refilling, task assignment, and printing.lt adopts multi-matrixDLP technology, sinking platform mode, and its mechanical design innovative reduces thepeeling force, safeguarding dental models, enhancing stability, and ensuring clean removalMoreover, its superior design ensures high reliability, stability, and straightforwardmaintenance,the highest efficiency on the market.

RF8800 Product Features:

- Advanced HADP™ technology, the largest DLP build volume 768*432mm.

- Printing 100 dental models within 60 minutes.

- 7×24 hours of continuous automated production.

R&D and Sustainability in Focus

RayForm emphasized investment in research and development (R&D), showcasing innovations in biocompatibility, low-shrinkage formulas, and eco-friendly materials. Sustainability was a key talking point, RayForm companies introducing recyclable packaging and low-waste resin systems as part of commitment to greener dentistry.

In the 2024 IFEMA Madrid Dental Exhibition highlighted how 3D printing dental resin is shaping the future of digital dentistry. From high-speed prototyping to automated aligner production, the advancements presented promise to transform clinical workflows and improve patient care. As dental practices continue to adopt digital tools, 3D printed resins will remain at the forefront of innovation.

To find out more about RayForm products and solutions, please visit our website, subscribe Email or contact us directly.

RayForm Technology

RayForm Technology

Leave a Reply