All website

In RayForm technotes center, you can learn more about the common FAQs of the 3D printing materials and 3D printer products. Follow our process engineers to explore more 3D printing techniques and knowledge.

Certainly. We are a technology-driven 3D printing material manufacturer and dental invisible orthodontic solution provider established in 2018, headquartered in Shenzhen, China. RayForm employs three PhDs and fifteen masters. The company is ISO 9001 certified and focuses on delivering high-quality, competitive products to global customers. You can learn more on our “About RayForm” page.

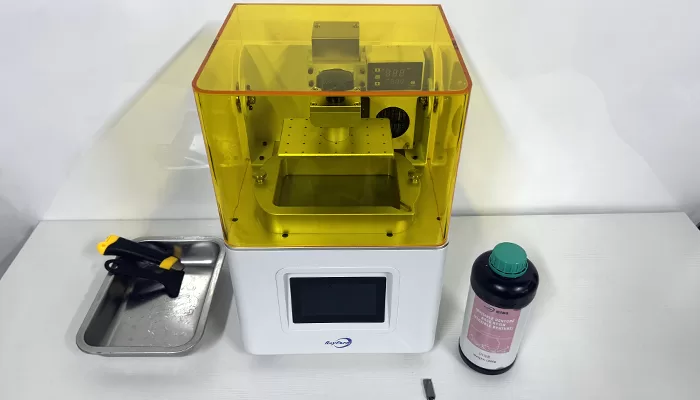

Our core products are dental 3D printing resins, 3D printers and clear aligners automated production solution products. We offer standard products and also support customized OEM/ODM solutions based on your specifications. Please visit our “All Products” section for a detailed catalog.

Yes. We place great emphasis on product quality and safety. Our products comply with international standards and hold certifications including CE, RoHS, ISO 9001, and FDA. Specific certifications vary by product. Please consult our sales team to obtain the specific certificates for the products you are interested in.

We typically provide samples to potential customers for quality inspection. The samples themselves are free, but you will be responsible for the express shipping costs. Once you place a formal order, any sample fees incurred may be refunded or applied as a credit toward your purchase. For standard products, production may take several days to several weeks; the specific lead time must be confirmed at the time of quotation.

Yes, we provide extensive customization services, including adjustments to capacity, materials, and more. Custom products typically have a minimum order quantity (MOQ) requirement, which depends on the product’s complexity. Please share your requirements with us, and we will provide you with detailed MOQ information and a quotation.

Our quotations are typically valid for 15 days, as raw material prices and exchange rates may fluctuate. After the validity period expires, we will need to provide a new quotation based on the latest market conditions.

We accept multiple secure international trade payment methods, including:

T/T (Wire Transfer): Most commonly used, supporting deposit + balance payment.

L/C (Letter of Credit): Suitable for large orders, requiring issuance through a reliable bank.

PayPal / Stripe: Suitable for small sample orders or trial orders.

Western Union: Suitable for small urgent payments.

Specific terms are subject to consultation with us or will be clearly stipulated in the contract.

For our first collaboration with new clients, the standard payment terms are:

40% deposit: Payable upon order confirmation.

60% balance: Payable upon presentation of shipping photos or a copy of the bill of lading, after production completion and prior to shipment.

For long-term partners, we can discuss more flexible payment arrangements.

Standard products typically require [e.g., 20-30] days after receiving the deposit. Custom products or orders during peak seasons may have longer lead times. The exact lead time will be provided in writing upon order confirmation.

We implement full-process quality management:

Incoming Material Inspection: Strictly control raw material quality.

Production Process Inspection: Conduct random sampling and critical point checks on the production line.

Final Inspection: Every batch undergoes a final inspection before shipment. We welcome customers to appoint third-party inspection companies (such as SGS, BV) to conduct pre-shipment inspections.

RayForm can arrange international shipping (by sea or air) and deliver globally. However, shipping costs, customs duties, and import regulations (such as chemical substance restrictions) vary by country or region, so you should check the details in advance.

We arrange the optimal logistics solution based on your requirements, order volume, and budget:

Sea Freight: Ideal for large or heavy shipments, offering the highest cost efficiency.

Air Freight: Suitable for small batches or urgent goods, providing the fastest delivery.

International Express: Perfect for samples and small parcels (e.g., DHL, FedEx, UPS).

We can arrange trade terms such as FOB, CIF, CFR, or EXW, with specifics agreed upon in the contract.

Once your shipment is dispatched, we will provide you with all necessary shipping documents, including the Bill of Lading (B/L) or Air Waybill (AWB) number. You can use this number to track your shipment’s status in real time on the carrier’s official website.

We guarantee the quality of our products. If any damage or quality issues occur, please immediately take photos or videos as evidence and contact us within 7 days of receiving the goods.

Yes. We provide a 12-month warranty for our hardware products, effective from the date the goods arrive at the destination port. The warranty covers quality issues arising from defects in raw materials, equipment, or manufacturing processes.

We are very pleased to collaborate with distributors and agents worldwide. Regional exclusive agency rights require evaluation based on your past sales performance, market development plans, and order commitments. We welcome detailed discussions regarding your business plans.

RayForm welcomes requests for factory tours and meetings from potential business partners and key customers. This is an effective way to build trust and verify production processes. If you wish to visit, please be sure to schedule an appointment in advance.

Photosensitive resin, also known as photoresist, is a synthetic resin material whose chemical properties (such as solubility) change in areas exposed to light (primarily ultraviolet light). Since it does not require thermal energy and produces extremely low carbon dioxide emissions, its environmental impact is relatively minimal.

The choice depends on your end use.

Creating physical models → Select High Temperature Resistant Dental Model Resin, Water Washable Model Resin.

Creating surgical guides → Select Surgical Guide resin (must be biocompatibility certified).

Creating temporary crowns → Select temporary crown and bridge resin (must be biocompatibility certified).

Creating flexible gingiva → Select gingiva model resin.

Be sure to consult our product manual or contact our technical support for precise recommendations.

Low-viscosity resins may develop sedimentation after extended storage, and colored resins may exhibit uneven coloration. Therefore, shake thoroughly for 1-2 minutes before use.

Low-viscosity resins may develop sedimentation after extended storage, and colored resins may exhibit uneven coloration. Therefore, shake thoroughly for 1-2 minutes before use.

The primary distinctions are as follows:

Flexural modulus: Guide plate resin > Model resin > Temporary crown resin

Fracture toughness: Temporary crown resin > Guide plate resin > Model resin

Water absorption rate: Model resin < Guide plate resin < Temporary crown resin

Curing shrinkage rate: Model resin < Guide plate resin < Temporary crown resin

Key impacts include:

Temperature: Optimal at 25±3°C. Low temperatures increase viscosity and cause detail loss.

Humidity: Recommended at 40-60% RH. Excessive humidity causes resin moisture absorption, compromising performance.

Temperature and humidity control: A temperature-controlled chamber is recommended to maintain material stability.

Storage Requirements:

Store in darkness: Keep in original packaging away from light

Temperature control: Store in an environment between 15-30°C

Seal to prevent moisture: Seal immediately after use

First-in, first-out: Use according to expiration date order

For 3D printers using LCD technology:

1,Understand the device’s light intensity. Lower light intensity requires correspondingly longer exposure times during printing, and vice versa.

2,Understand wavelength characteristics. The 385nm wavelength has weaker penetration, making it suitable for transparent resin products. The 405nm wavelength has stronger penetration, making it more suitable for printing colored resin products.

Identify your 3D printer model, the slicing software used, the slicing file, and the STL file for analysis. Contacting us directly for support.

1,Long-term resin use may cause sedimentation, which can wear down release film. Try replacing the release film.

2,Insufficient model supports may lead to structural weakness. Try adding supports to the model file.

3,Excessive model weight may cause platform instability during printing.

Contact us immediately for further assistance.

Because the resin tank must be cleaned after each print to prevent residual cured material or debris from affecting subsequent prints and to avoid damaging the release film or screen.

Surface blurring may be caused by overexposure.

1,Calibrate the resin exposure time promptly.

2,Check the clarity of the release film.

3,Try extending the bottom exposure time by 10 to 20 seconds until the object adheres firmly to the platform.

Contact us for support based on your specific usage environment.

This is primarily caused by insufficient exposure. Try extending the standard exposure time by 1 to 2 seconds and set the model support density to 75% or higher. Contact us for support based on your specific operating environment.

1,Re-adjust the leveling.

2,Gradually increase the bottom exposure time by 10 to 20 seconds each time until it adheres firmly to the platform.

Contact us for support based on your specific operating environment.

Incomplete cleaning can leave uncured resin residue on the surface of the model, which not only creates a sticky texture but also interferes with the subsequent secondary curing process, resulting in a tacky surface. More seriously, residual resin may cause skin allergic reactions and compromise the dimensional accuracy and surface details of the restoration. To ensure effective cleaning, it is recommended to use isopropyl alcohol with a concentration of 95% or higher, employing a two-step process of pre-washing and precision washing, controlling the cleaning time to 2-3 minutes, and maintaining the cleaning solution temperature between 20-30°C.

Secondary curing requires professional light-curing equipment with a wavelength of 395-405 nm. Depending on the size and complexity of the model, the curing time is typically controlled between 5-15 minutes. For larger models, it is advisable to use a curing chamber with a rotating platform to ensure even exposure on all sides. During the curing process, temperature control is crucial to avoid exceeding 40°C, as higher temperatures may cause model deformation. The adequacy of curing can be determined by checking for a non-tacky surface, testing hardness values with a durometer, and observing color uniformity.

Model deformation is often caused by improper support structure design or incorrect curing parameters. Preventive measures include optimizing support structure and orientation, adopting a gradual curing program, and avoiding excessive temperatures. For already deformed models, professional repair resin can be used for correction, or shape adjustments can be made by heating and softening the material. It is important to consider the shrinkage characteristics of the model before printing and compensate through design to reduce the risk of deformation.

Surface defects often stem from inadequate cleaning, improper support removal, or rough post-processing. Solutions include ensuring the use of fresh cleaning solution and thorough cleaning, carefully removing supports and polishing contact points, progressively polishing the surface with sandpapers of varying grits, and applying a specialized protective coating if necessary. During handling, it is essential to maintain gentle techniques to avoid secondary damage to the model.

Safety precautions are critical. Nitrile gloves and protective goggles must be worn to avoid resin contact with the skin and eyes. The operating environment should be well-ventilated, and masks should be worn when necessary. Lab coats should be worn to prevent resin splashes on clothing, and the workspace should be equipped with eye wash stations and emergency showers. All operators must undergo safety training and be familiar with emergency procedures.

Cured models should be stored in a light-proof environment with constant temperature and humidity, ideally at 15-25°C and 40-60% relative humidity. Models should be prevented from squeezing each other, and independent packaging boxes are recommended. For waste resin and cleaning solution, complete curing treatment must be performed first, followed by classification and collection as chemical waste, which should be disposed of by qualified agencies. Direct disposal into drains is strictly prohibited.

Cleaning equipment requires regular replacement of cleaning solutions and thorough tank cleaning. Curing equipment should be periodically inspected to ensure ultraviolet light intensity meets standards. Ventilation systems must be kept unobstructed, with filters replaced regularly. All equipment should have maintenance records, and comprehensive inspections and calibrations should be conducted every six months. After daily use, equipment surfaces should be cleaned promptly, and the work area should be kept tidy.

This website uses cookies to improve your browsing experience. By continuing to use this site, you accept the use of our cookies. Data collected from this website is processed and stored in the United States.

More